06/04/2018

Sika masters all the process steps needed to print concrete on an industrial scale, and is leading the way in 3D concrete printing technology.

3D concrete printing allows architects to realize the most challenging shapes, and with Sika’s technology totally new design flexibility can be achieved. Complex shapes can be realized economically and completely homogeneous concrete can be printed.

Industrial Scale Production

Traditionally placed concrete has long been the most economic method of construction. If 3D concrete printing is to compete with this tried and trusted solution, then structures need to be printed efficiently. This is precisely what Sika’s technology is designed to achieve.

"We have now achieved our ambition. With our technology, it is possible to print concrete so rapidly, inexpensively, and precisely that it can be used on construction sites. Digitalization is changing every aspect of construction and the entire life cycle of a building, from the design process and automated construction all the way to maintenance. Building processes can be optimized and time and money saved. At the same time, these advanced technologies offer greater design flexibility." Frank Hoefflin, Sika Chief Technology Officer

Sika as Technology Leader

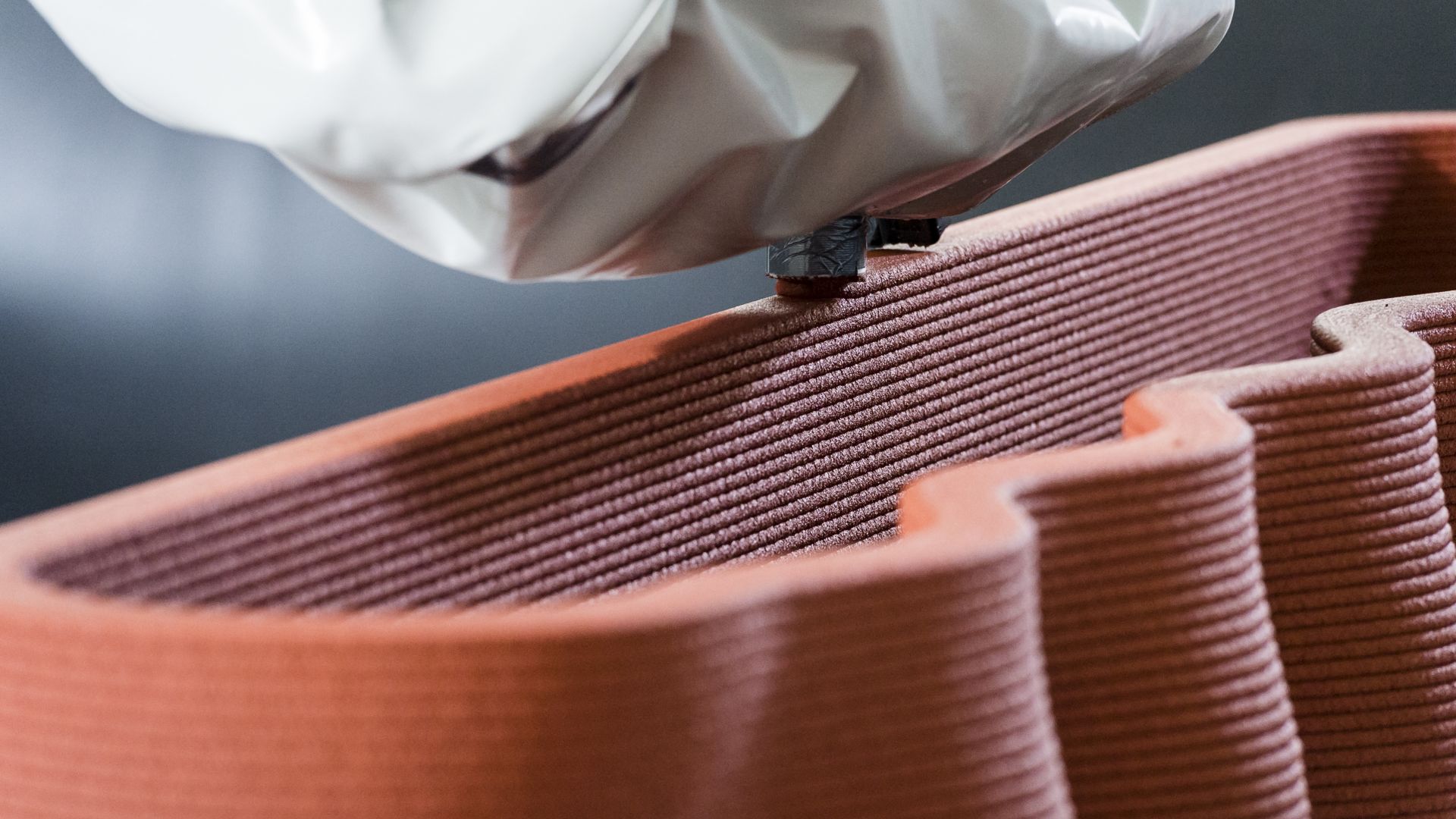

The most challenging part of the 3D printing process is what happens in the print head, which was developed by the 3D research team at Sika’s technology center in Widen, Switzerland. In this high-performance tool a range of additives is mixed with the mortar. The material cures within seconds and bonds with the layer previously applied.

It is thanks to this expertise that Sika is leading the digitalization and industrialization of concrete construction. The company’s entire know-how, built up over decades, has been brought together in its 3D printing technology, making Sika the only company capable of supplying all the technologies needed for industrial 3D concrete printing from a single source.