Fiber-reinforced concrete is ideal for improving the durability and toughness performance of concrete and mortar. Fibers in concrete help reduce shrinkage cracks, increase strength, increase energy absorption and reduces dangerous spalling at high temperatures.

Sika is the leading company for fiber-reinforced concrete solutions. Our global footprint and a fiber production facility in all regions means we are ideally placed to support your project.

Local technical support is valuable to our customers. As a multi-discipline construction materials company, Sika offers a full range of solutions for concrete including admixtures, curing agents, mold release agents, floor hardening and coatings, joint sealants, concrete protection and more. Our job site presence and training support helps ensure you have the right products for a successful project.

Main Benefits of Sika Fiber Reinforced Concrete

There are multiple reasons for adding fibers in concrete. One of the main benefits of fibers are the homogenous distribution in the concrete. Other benefits include:

- Better cohesion of the fresh concrete

- Control and reduce crack sizes due to early-age shrinkage

- Improve flexural and shear strength

- Improve load capacity and ductility

- Increase toughness and abrasion resistance

- Increase resistance to explosive spalling

- Replace or partially replace traditional reinforcing steel

- Save time in the construction process and reduce costs

Selecting the Right Type of Fiber

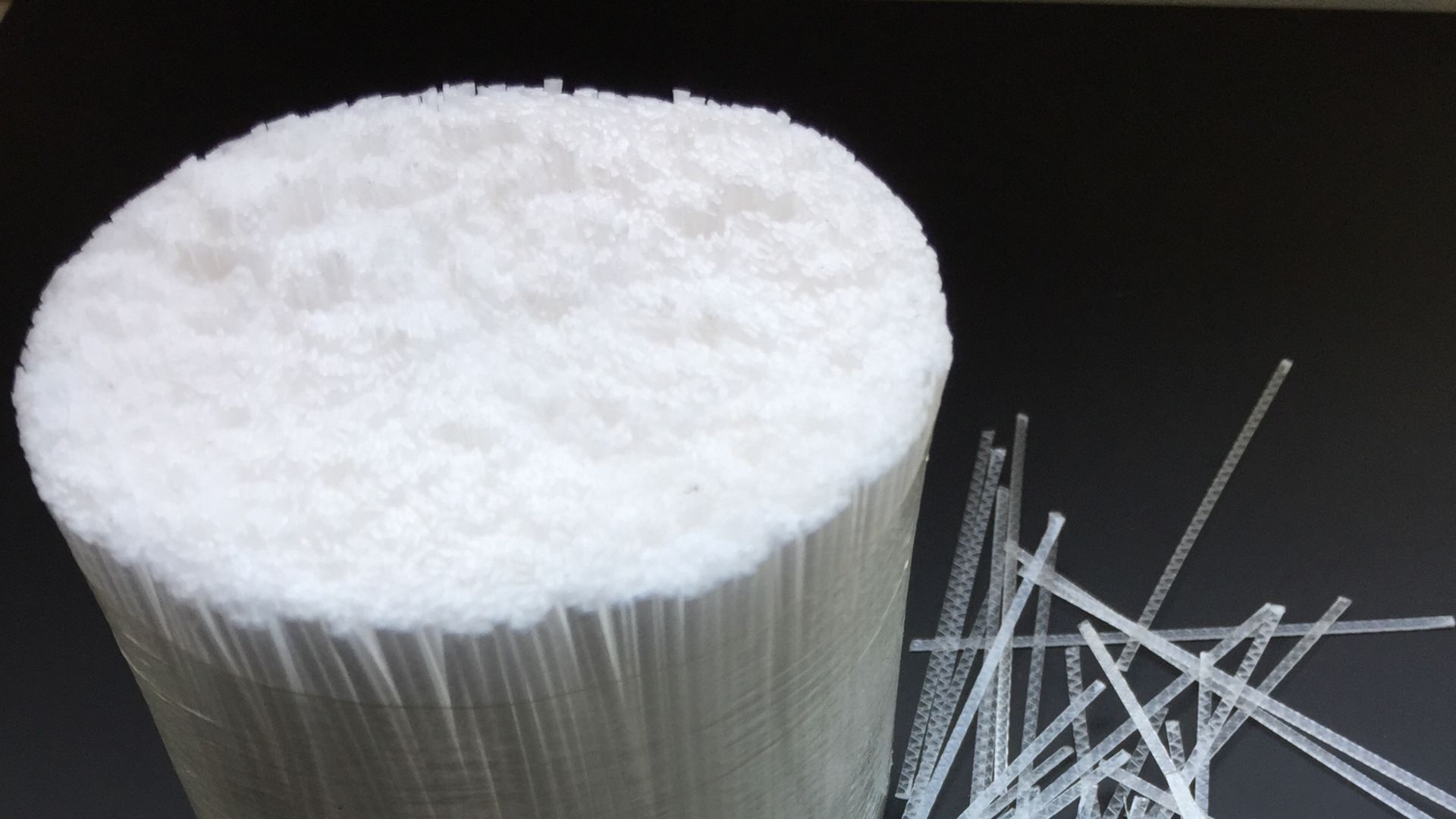

Choosing the right fiber mostly depends on the type of application. The main types of fibers offered by Sika are synthetic polypropylene and steel fibers.

Different fiber types are used to deliver different performance requirements. Short, thin synthetic fibers are used to reduce the effect of crack reduction explosive spalling, while long synthetic or steel fibers are used to increase the concrete strength and energy absorption. Sika is one of a few suppliers providing solutions for all requirements as well as other special types and blends of fibers.

In addition to the material, fibers are classed into two main groups - micro and macro fibers. According to European Standards, a micro and macro fiber is distinguished by the diameter.

Synthetic micro-fibers

Micro-fibers have a diameter less than 0.3 mm and are either monofilament or fibrillated. Micro-fibers should be used for plastic shrinkage control (cracking that can occur in the first 24 hours of concrete curing), impact protection, and reduction of explosive spalling during a fire. The fibrillated micro fibers are often used in replacement of the lightest welded wire fiber for temperature and shrinkage characteristics.

- Reduces plastic shrinkage cracks

- Reduces plastic settlement

- Reduces bleeding

- Alternative to crack control mesh

Synthetic macro-fibers

Structural macro-fibers have a diameter greater than 0.3 mm. Macro-fibers are used as a replacement for temperature and shrinkage reinforcement or as structural reinforcement in concrete or shotcrete. Macro fibers are used where an increase in residual (post-cracking) flexural strength is required (e.g. ASTM C1609 or EN 14845).

- Increases flexural strength

- Increases impact resistance

- Increases durability

- Increases tensile strength

Steel fibers

Steel fibers may be collated (glued) together in a clip. The collation of the fibers does not improve performance of the fiber-reinforced concrete. Collated fibers improve the ease of mixing of high aspect ratio fibers. When added to the concrete mix, the bundles are spread throughout the concrete. Continued mixing breaks apart the clips to allow individual fibers to separate quickly throughout the mix.

- Enhance concrete in its hardened state

- Provide ultimate performance under intense loading conditions

Related Products from Sika

| Concrete admixtures | Optimizing the fresh and/or hardened properties of concrete using plasticizers, water reducers, accelerators, retarders, air-entrainment, shrinkage reducers, antifreeze, corrosion inhibitors | Sika® ViscoFlow®, Sika® ViscoCrete®, SikaControl®, Sika® FerroGard®, SikaRapid® |

| Pumping | For use with unfavorable aggregates and protecting equipment from excessive wear. Maintains internal cohesion. | SikaPump® Sika® Stabilizer |

| Curing | Liquid agents or sheets protecting the slab from premature drying. | Antisol®, Sika® Ultracure |

| Mold release | Extend longevity of formwork by preventing concrete from sticking to the mold. | Sika® Separol® |

| Joints | Preventing dirt from filling the joint, accommodating movement and protecting the edges allowing smooth joint crossing. | Sikaflex® |

| Surface hardeners | Improve slab life span by impregnating the surface or by forming a monolithic layer. | Sika® CureHard, Sikafloor® |

| Surface coatings | Increase resistance against mechanical and chemical attack. | Sikafloor®, SikaScreed® |

| Protection | Improve aesthetic appearance or extend the durability of concrete by protecting from aggressive environments | Sikagard® |

| Repair | Improve aesthetic appearance or repair imperfections | Sika MonoTop® |

SikaFiber® Technical Support

Sika fiber-reinforced concrete is widely used for various functions and requirements all around the world. This is particularly the case in tunneling and mining, precast construction, flooring and all types of projects requiring excellent fire resistance.

Sika’s technical expertise and extensive practical experience in the design, selection and installation of all different types of fiber-reinforced concrete and mortar is evident in many successful projects on every continent.

Local Contact

Contact a Sika expert near you for technical support and locally available products and systems.

Global Support

Contact Sika's global representative in case you need support on an international project by filling out the form below.