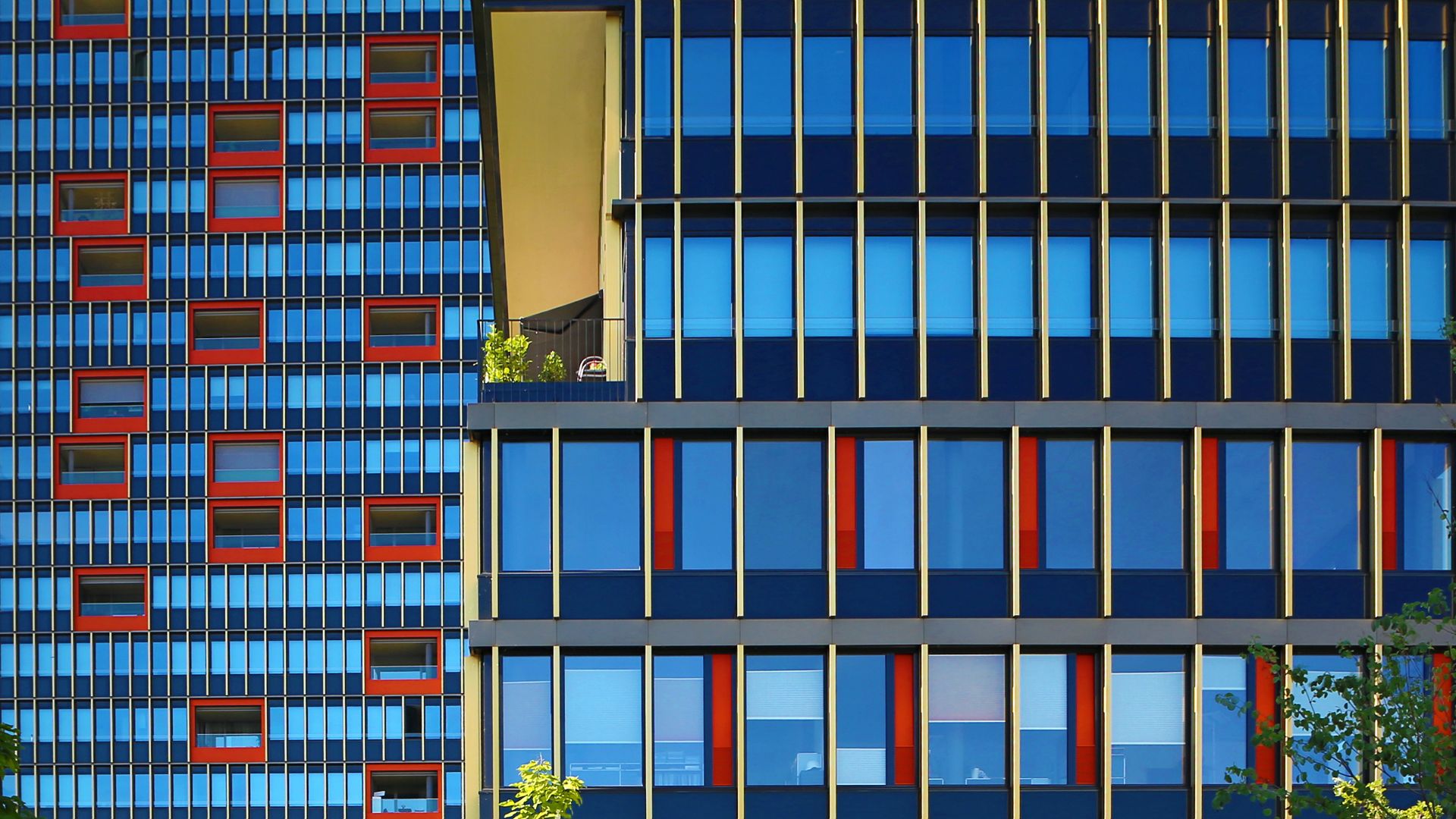

Glass facades are an integral part of modern architecture. With glass curtain wall construction, an ideal balance is found between aesthetic appeal and energy efficiency. Bonding the insulating glass units (IGUs) or double glazing to the window profile is the latest glazing technology for windows. By using the structural properties of the glass for the window performance, it leads to slimmer frames and state of the art energy ratings.

How Structural Glazing Comes Together

Glass curtain walls consist of facade elements, which are factory-produced and mounted to the carrier structure of the building. Eventually, weather sealants seal the respective elements. The glass facade elements are produced by bonding glass panels to the metal adapter profile with silicone adhesives.

The elastic joints produced with Sikasil® SG silicone adhesives accommodate movements of the construction elements resulting from temperature changes, moisture, shrinkage of construction materials, sound, wind and vibrations permanently.

Four Principle Curtain Wall Technologies

Four-Sided Structural Glazing

Optimum transparency and frameless appearance

Four-sided structural glazing is impressive because of its monolithic, frameless appearance. The large-format glass panels are bonded on all four sides to an adapter profile and have no visible frame.

Two-Sided Structural Glazing

Optimum safety by mechanical fixing

Two-sided structural glazing offers transparency and maximum safety. The glass panels are bonded on the vertical sides and mechanically fixed on bottom and top to an adapter profile.

Point-Fixed Glazing

The lightness of glazing by point fixed glazing

For maximum transparency of the glass panels on the façade and inside the building, the glass pieces are either mechanically fixed or high-strength bonded to metal fasteners.

Structural Window Bonding

Slim design by structural window bonding

Structurally bonding the insulating glass unit into the sash frame has big advantages over the other technologies. Read on below to learn more.

Competitiveness through Structural Window Bonding

Structural bonding of the IGU into the sash frame has many benefits, including:

- Less material costs (up to 30%)

- Automated glazing process

- Best thermal and sound insulation

- Improvement of thermal insulating values and solar heat gains

- Increased transparency by allowing slim sash design

- Increased service life by minimized peak stress and high window stiffness

- Almost maintenance-free windows

The System Principle

The Sikasil® SG and IG Silicones Have Many Advantages

Sika’s structural glazing silicones (Sikasil® SG) and insulating glass secondary sealants (Sikasil® IG) are highly specialized products dedicated to structural glazing and insulating glass application and offering you unique possibilities for design, energy efficiency and durability of your facade.

- Durable and extremely strong

- Outstanding weathering and aging resistance

- Extremely good UV and oxidation stability

- Good chemical resistance

- Resistant and flexible with extreme temperature fluctuations from -50°C to +150°C

- Low shrinkage in vulcanization

- Long-term resistance to continuous rain

Sika’s Worldwide Footprint

Sika is one of the market leaders in sealants and adhesives for curtain wall production. We supply leading curtain wall fabricators worldwide. Our Sikasil® SG and IG silicones are also present in many facades around the globe.

Sika’s Experts Provide Assistance to Benefit your Business

Local Contact

Contact a Sika expert near you for technical support and locally available products and systems.

Global Contact

To learn more about Sika products and systems for structural glazing, to see reference projects or to contact the technical support team, go to our partner page.